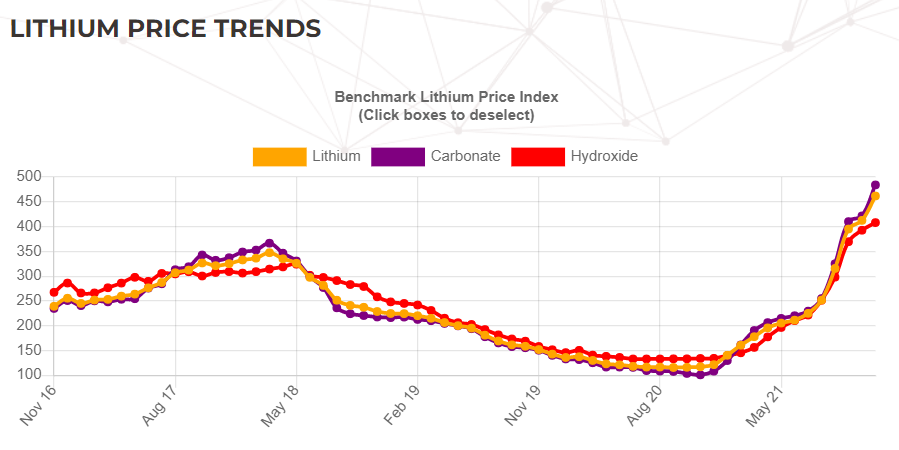

Graphic from Benchmark Mineral Intelligence.

The lithium-ion industry is exploding in demand as over 200 Li-ion “Gigafactories” are either in operation or have been announced worldwide. Realizing that the future of mobility and energy will rely on battery storage, countries, regions and entire continents are vying to build robust and reliable supply chains from mining to manufacturing. The problem is that while it takes 24 months to build a gigafactory, it takes 4-7 years to open a lithium mine, and recycling technologies aren’t yet ready to fit into the supply chain economically. Hence, we are a this inflection point as tracked by Benchmark Mineral Intelligence. After enjoying generally falling prices for more than a decade, lithium materials are suddenly becoming scarce.

While Li-ion is the only commercial battery technology with the energy density necessary for high-range vehicles, these rising prices and the demand they reflect will open the door to better technologies for applications like grid and stationary storage. Up until now, rapidly falling prices, partnered with high efficiency and small form factor, have driven li-ion into markets and applications that don’t necessarily call for that technology. Particularly for large-scale applications like grid storage, cheaper, safer, longer-lasting and much more sustainable options like Zinc-Bromine and Zinc-Air make more sense, and they can help free up lithium supply that might otherwise be squandered on the grid.

To combat climate change, the world desperately needs more electric vehicles, and lithium alone can answer that call. The increasing adoption of Zinc batteries can help to make sure that all possible lithium is dedicated to those applications.